Startseite » Products » 3D-Orthoses

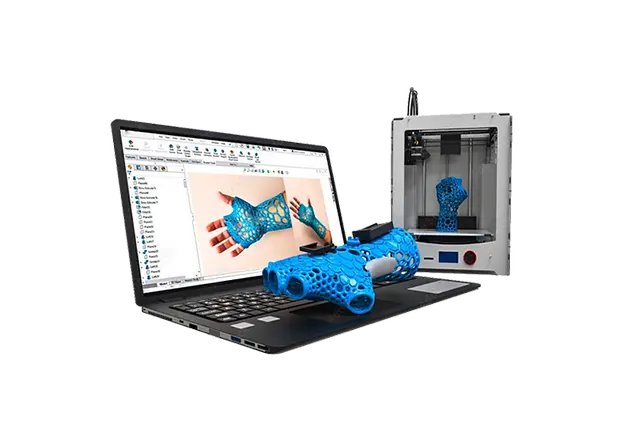

The future is 3D–Orthoses tailored and precise.

With custom-made orthoses, we offer a tailored solution and care. The production takes only a few seconds, enabling efficient time savings. For this, we use a 3D scanner to capture the exact contours of the body part for which the orthosis is designed.

Scanning technology instead of plaster casts.

The basis for the orthosis design is a 3D scan of the relevant body part. The scanning process is fast, clean, reproducible, and also comfortable for the patient.

Complete perforation

Low weight

The combination of digital design and additive manufacturing offers the possibility of weight-optimized solutions. By strategically reducing material usage, the weight of the orthosis can be minimized, enabling resource-efficient production.

Reproducible at any time

Integrated joint

Our custom-made joint boxes allow the integration of all standard joint systems into the orthosis, as close to the joint as desired. This leads to a slimmer overall design of the orthosis and improves force transmission.

Fully waterproof

High acceptance

A symbiotic harmony of modern design, fit, and functionality. Together with your user, you have complete freedom to choose the color and design of the orthosis. Through individual customization, a medical aid becomes a fashionable accessory that people enjoy wearing and showing off.

Individualized closures

By integrating movable deflection elements, the closures optimally adapt to the body’s anatomy, offering the option of individually selecting the closure strap width.

Edge design

By thinning the edge areas, we achieve weight reduction, a slimmer appearance, and quicker, simpler post-processing. Additionally, edging helps minimize pressure on soft tissues.

Process of care

Scan at Orthorama AG

3D scan for precise analysis

Third-party institution

Custom manufacturing

Composition

Combining all data

GL Analysis

Internal quality assurance

Post-processing

Final polishing and quality check

Assembly

Precision assembly of all parts

Repair station

Service and adjustments

Analysis incl. biomechanical measurements

Comprehensive movement analysis